|

||

According to a recent report by National Geographic, 91% of plastic waste is not sent to recycling facilities. Therefore, local governments are implementing various policies to increase the recovery rate of recyclable resources and encourage residents to actively participate in the virtuous cycle of resources. The most effective of these is the installation of automatic recycling machines, a system that many countries are actively adopting.

AI-powered unmanned recycling collection system that dramatically increases recycling recovery rates

Unattended collection and shredding of PET, PS, PP, PE, and other materials of all types and colors

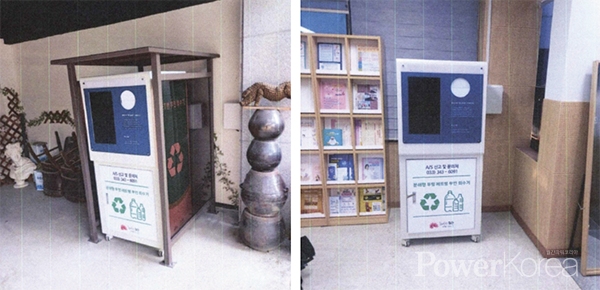

Gtec has developed an AI-powered unmanned recycling collection system that dramatically increases recycling participation and recovery rates. The company has developed an unmanned resource recovery system for disposable products and supplies them nationwide. “The existing system had a number of high collection standards, which limited the amount of recyclable waste collected even when unmanned collection machines were installed. In addition, there were many cases where recyclable waste was not recycled due to contamination or incorrect collection. We are continuously working to solve these problems through technical and system improvements” says Gtec chairman Bang Jun-ho. Unmanned recovery machines can generally be divided into two types: compression type and shredding type. The compression type is a method of compressing the recovered resources directly inside the machine, and the shredding type is a method of shredding them in the form of flakes. Unmanned collection machines were mainly installed with a compression method, but the plastic bottles collected without removing the caps were compressed inside the machine, causing them to burst with a loud sound.

|

AI hyperspectral shredding plastic sorter automatically sorts plastic pieces by material

From unattended collection to shredding, transfer, and recycling

Gtec’s unmanned PET bottle recycler is shredded, so it doesn’t have any of the disadvantages of the compression type mentioned above. This means that plastic bottles of any color, with or without labels, and even children’s toys, cosmetic containers, and food containers are collected and shredded. However, the government subsidy of 10 won is not available for clear plastic bottles. Plastic bottles that meet the criteria can earn reward points through mobile phones, local cards, transportation cards, and local garbage disposal cards. The reason it is able to collect and shred all plastic is because it has built its own hyperspectral pulverized plastic sorting system that can accurately select shredded flakes. The Hyperspectral Pulverized Plastic Sorter is the world’s first artificial intelligence solution that uses hyperspectral cameras and A.I. vision solutions to automatically classify and sort plastic pieces such as PET, PS, PP, PE, ABS, PVC, etc. by material, and was developed by a small enterprise in South Korea. Gtec’s unmanned bottle recycler is equipped with a self-developed and patented crushing blade. The special blade bites into the waste plastic and shreds it precisely without bouncing, and the heat generated does not cause the plastic to burn. The blade is made of stainless steel, which is resistant to corrosion and abrasion, and was developed in consideration of corrosion resistance and moldability. The shredder’s blades perfectly comply with the environmental standards of 0.8 to 1.2 cm in size (the size can be changed upon customer request), holds approximately 800 PET bottles, and shreds at a high speed. It can crush up to 50 2L PET bottles per minute, and after crushing, the volume is reduced to about 1/15 of its original size. In addition, the data of device users and collection resource input (discharge time, reward points) are transmitted to the control system, and a monitoring system related to recyclables using big data is operated.

|

From unattended reclaimers to sanitizing and disinfecting contaminated water

Installed in public institutions and highway rest areas to significantly increase recycling collection rate

Gtec’s unmanned reclaimers clean the contents by themselves, and the contaminated water is disinfected with an internal UV sterilizer to remove all odors, completely eliminating the discomfort caused by contamination. This is because the dirty water is completely absorbed from the inside, and the dirty water is not discharged to the outside at all, maintaining a pleasant environment at all times. When the shredded flakes are more than 80% full, an automatic notification is sent and Gitec collects them by itself. The device administrator is automatically notified of the collection amount every month. The collected flakes are then handed over to final recycling companies such as SK, Hyosung, Kolon, etc. to be recycled into various textile chemical products such as clothing and straws. Municipalities are also increasingly interested in installing them because of their ability to increase recycling collection rates without the need for special management. The company’s unmanned recovery machines are currently being successfully operated in Gimhae-si, Jeonju-si, Gongju-si, and Donghae-si, and are scheduled to be installed in 26 rest areas under the Jeonbuk headquarters of the Korea Expressway Corporation within this year.

|

Unattended cup reclaimer

Collecting waste bottles and disposable cups at the same time, ideal for disposable cup deposit

The company also produces unattended recycling machines for cans, paper cups, and disposable cups. Last year, 940 million single-use cups were used in 17 cafes and franchise restaurants that have signed agreements with the Ministry of Environment, of which 44 million were recovered, a recovery rate of less than 5%. It is reported that the use of disposable cups in Korea is a whopping 3.5 billion per year. The Seoul Metropolitan Government has proposed a “disposable cup deposit system” that will require cafes to pay an additional 300 won deposit for disposable cups used in cafes starting in 2025, and the collected disposable cups will be collected, transported, and recycled. Participating stores will also receive priority for renting multi-use cup washers in their stores. In addition to the unmanned recycling machine for disposable cups, Gtec has developed an unmanned recycling machine that can collect both plastic and disposable cups at the same time, and plans to install it in cafes and major regional bases nationwide. The company plans to dramatically increase the recovery rate of disposable cups by collecting all disposable cups equally and rewarding them accordingly.

|

Smart House for resting and recycling

The smart house that the company is preparing is a fully air-conditioned rest area with amenities such as heated and cooled chairs and cell phone chargers, along with a variety of unmanned resource recovery machines so that citizens can relax and earn financial rewards for recycling. The company has also developed an amphibious electric cart and an electric ferry, the latter of which was developed in response to an export request from Tajikistan. It is an amphibious electric cart that can be operated in all seasons and weather conditions using eco-friendly electric energy. An electric boat is a product that is equipped with an electric function on a boat that is used as a mobile equipment for collecting small fish in the tidal flats. This is a product designed to improve the tidal flat work environment and respond quickly with quick mobility in the event of an emergency, and was developed at the request of the Coast Guard’s special rescue unit. This is a new leisure product that can also be utilized as a leisure product, and the company has launched the first prototype and is finalizing improvements.

신태섭 기자 tss79@naver.com