|

||

KTech Rober supports successful business with innovative, organized, multi-variety, low-volume production system

KTech Rober provides innovative and systematic multi-product, low-volume production systems. The company supports e-Manufacturing, R/P NC Master, Desing Mock-up, 3D Scan & Modeling, and Vacuum casting technologies, and has signed MOUs with universities and research institutes to support the development of high-quality prototypes for many companies based on equipment and technology optimized for multi-product, low-volume production. Prototyping and testing is the most important step before launching a new product. Once the product is developed, it is time to build a prototype and test it, which is the most exciting and nerve-wracking moment for any developer. If the prototype you have spent a lot of passion, effort, money, and time creating and developing exceeds your expectations, the chances of your business succeeding are very high. “The quality of the prototype is very important. It gives us the opportunity to identify and improve various errors and problems before the product is released, and a well-done prototype will result in a well-done product when it is mass-produced. However, in the real world, the finished product is often different from the prototype. A high quality prototype can save time and money and increase market satisfaction with the product.” says Kang. After improving the various problems of the prototype and going through many trials and errors, the product is ready for mass production, and saving money and time in this process is the core of the business. For small and medium-sized enterprises, investing too much money in the prototyping process can result in huge losses even before the product is mass-produced. Therefore, the process from mold making to prototype testing should be simple and clear, and close communication with the prototype manufacturer is essential.

|

Vacuum mold, 3D print, CNC mockup and more

Proprietary vacuum mold technology that is 10x faster and significantly less expensive

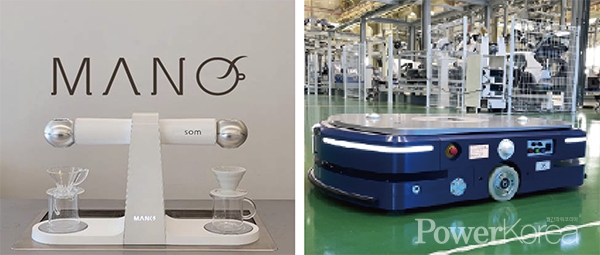

KTech Rober offers a wide range of mold making services, including vacuum molds, 3D printing, and CNC mock-ups for prototyping and low-volume production of a wide variety of products. In particular, the company’s vacuum mold technology has been around for 40 years and is considered one of the most advanced systems in the industry and a market leader. Vacuum molds are a method of producing products by injecting a liquid material mixed with a curing agent into a silicone mold under vacuum and curing it. By using a silicone mold for a master made by 3D printing, it is possible to secure a small amount of products in a short time, and it is characterized by using thermosetting resin rather than thermoplastic resin. The production speed of the mold is more than 10 times faster, and the cost is incomparably lower than that of general injection molds. In addition, a single mold can produce about 30 products, and it is considered the best solution for low-volume production of various products because it can quickly respond to design modifications and material changes. “Vacuum mold technology has the advantage of being able to produce prototypes quickly and with high precision, dramatically reducing the cost and time of prototyping, and offering a wide range of materials depending on the product and application. Another advantage is that it produces robust parts, and because the parts are molded in a vacuum, air bubbles in the liquid resin can be minimized. In addition, it allows for thinner and more precise machining than injection molding, and it is much less expensive.” says Kang. Vacuum molds can be applied to any industry. In particular, it is best suited for new businesses, and Kang is focusing on the rapidly developing fields of robotics and medical devices. The robotics and medical device sectors are typical low-volume, multi-product industries with a large number of products being developed. Therefore, it is predicted that vacuum mold technology will be most needed in the future, even when considering the design aspects of service robots.

|

Creating a systematic, one-stop manufacturing system that combines vacuum casting, 3D printing, and CNC mockup.

Active participation in the planning and design phase, resulting in more complete prototypes

The company also has many differentiators in its 3D printing and CNC woodworking business. Kang has a great deal of knowledge and know-how about the equipment, having been entrusted with the 3D printing equipment at Hanyang University’s Robotics Support Center in the past. Using the company’s CAD/CAM system, 3D printers can be used to design and fabricate geometric shapes, while CNC mock-ups are used in the new product development stage to create prototypes that are exactly the same as the design drawings, so they accurately reflect the concept of the product and are exactly the same as the product that will be mass-produced and sold later. The company is also uniquely skilled in reverse engineering. This is a technology that allows you to reverse engineer a product that only exists as an idea or a shape in your head and mass-produce it, and many developers’ products have been produced through KaneCover. The company has secured a variety of equipment such as rapid molding (capable of producing small quantities and various types of actual functional parts, master sample production for vacuum molds), rapid molding system B (design and its verification master sample production for vacuum molds), non-contact 3D optical scanner (3D modeling of products and models), CNC machining system (automotive parts processing, 3D machining of electrical small parts, deep hole and small diameter drilling and deburring swarm processing), and has completed a systematic all-in-one production system by integrating them. The company provides efficient prototyping services through interconnection with companies, which means that it does not simply produce the design data provided by the customer, but also actively participates in the design and its process. Even if a mold is made to produce a product exactly as per the design, changes in overall stress can cause the product to warp or deviate in dimensions and thickness. KTech Rober has turned decades of data into big data and is actively involved in the planning and design stages to help create more complete prototypes. This type of linkage system is completely unheard of in the mold industry, and customers who were initially skeptical of the service are now more willing to cooperate once they see the results that lead to more complete prototypes.

|

Making the mold industry a smart factory through smart management innovation

Continuing to focus on research and development with the goal of helping customers increase their competitiveness

Kang summarized the production system, from quality control to production, in a book and created a manual for employees. He plans to transform the mold making into a smart factory through so-called “smart management innovation” instead of limiting it to a simple technology. This is to help customers succeed even more by programming all stages from ordering to production, quality control, and verification. In particular, as we enter the era of low-volume production of various products, companies are struggling, and the domestic manufacturing market has shrunk due to the onslaught of low-cost products from China. The robotics and artificial intelligence sectors are also on the verge of being overtaken by China’s cheap production structure. Therefore, the company aims to help the domestic manufacturing industry get out of the crisis by providing excellent prototyping and multi-variety low-volume production systems.

|

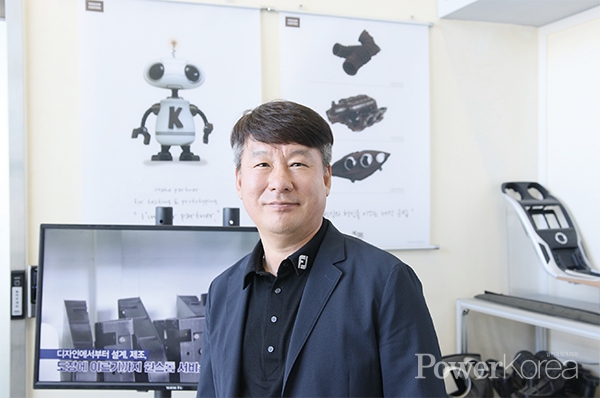

| ▲ KTech Rober / CEO Kang Dae-hee |

“E-manufacturing prototyping can increase productivity by 40 to 80 percent compared to traditional methods such as cutting and machining. The fierce competition in the market demands a dramatic reduction in product development time and start-up period. We will continue to focus on research and development with the goal of helping our customers increase their competitiveness by being able to respond to the rapid changes and diverse needs of the market.” says Kang.

신태섭 기자 tss79@naver.com