|

||

Automobile maintenance can be shortened and stability can be secured depending on the maintenance equipment. Since it is directly related to safety, automobile maintenance equipment must always be kept in the best condition. Shinchan Hydraulic Maintenance Equipment provides safe and various best maintenance equipment with 20 years of know-how.

|

Unparalleled technology brings a new paradigm to automotive mechanics

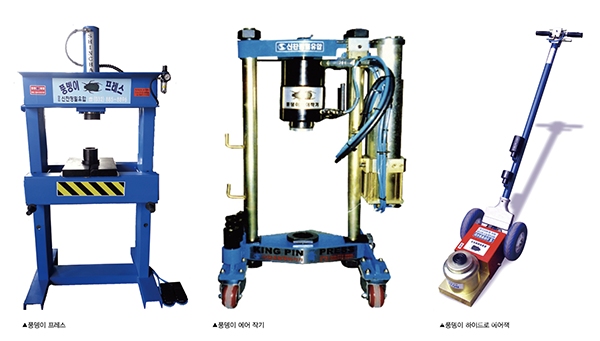

Regularly checking and replacing major parts such as brakes, engine, tires, etc. can increase energy efficiency, reduce fuel consumption, prevent accidents on the road, and keep your car performing optimally at all times. To maintain your car regularly, you'll need good car maintenance tools. Shinchan Hydraulic Maintenance Equipment, located in Asan, Chungcheongnam-do, is an automotive maintenance equipment company that specializes in manufacturing and distributing more than 80 types of maintenance equipment for large vehicles, as well as exporting and importing various hydraulic maintenance equipment, special machines, air machines, and other core maintenance equipment for automobiles. “We are specialized in manufacturing, distributing, exporting and importing scarab cutters, hydro jacks, presses, furring jacks, impact mounts, king pin presses, wheel drum separators, lining machines and impacts. With over 20 years of experience and technology, we are supplying quality-first machines and doing our best to satisfy our customers.” says CEO Lee Meong-shin.

|

The company offers the scarab hydro air jack, which features air-powered automatic pumping and hydraulic cylinder raising and neutral lowering with a simple valve operation for lifting from bongos to extra-large vehicles; the 2-Stage and 3-Stage Air Jacks, which make repairs and parts changes easier and faster for buses and lowered vehicle undercarriages, Impact jacks with a bearing design for vertical and horizontal movement that minimizes the physical effort of the mechanic to hold and operate the impact; flatbed mission jacks with a hydraulically adjustable tilt saddle for underbody and motion work; kingpin presses for removing and installing kingpins on heavy trucks and buses, with easy angle adjustment and column removal; and lining riveting machines for removing and installing lining rivets, wheel drum separators that can be operated by a single mechanic while maintaining leveling when removing the drum wheels of buses and large vehicles; fulcrum jacks that can lift the body of vehicles such as the bumper frame or front axle of trucks and other vehicles using only air and no oil, and can be used anywhere and in any space as it is mobile rather than a fixed lift; and foot-pedal automatic presses that use air-driven hydraulic pumps for bushing and bearing work, providing higher speeds with less effort. The company manufactures, distributes, exports, and imports more than 80 types of maintenance equipment used in the maintenance of general automobiles to trucks and heavy vehicles, including ultra-compact impacts, small, medium, and large impacts, air ratchets, oil and copper transmissions, barrels, detachers, and pit jacks optimized for lifting trucks and heavy vehicles. Lee was the first in the country to introduce and commercialize the Pit Jack, a self-propelled machine that is much safer and reduces work time than heavy lifts when servicing large vehicles. “Pit jacks for heavy vehicle maintenance are much safer than heavy lifts and more efficient with the addition of the hurem jack and mission jack. It is pneumatically operated, so the smooth up and down motion is very convenient to work with, and it can be used in three stages of 100T, 50T, and 25T to suit the environment. In addition, the operator can easily move back and forth in the pit, so it is excellent for heavy-duty vehicle underbody maintenance and lower body maintenance such as mission removal, spring work, and frame jacks. Most importantly, it can be operated from inside or outside the pit because it is operated by remote control, and the operator can unload the vehicle after working outside without having to enter the pit, which is safe for the operator.”

|

Putting customers first and meeting their needs

“The most important part of our business is to get back to the basics and satisfy our customers' needs through trust. We will do our best to understand our customers' needs, provide products and services that meet them, listen to their feedback, and always strive to do better from their perspective.” It is no secret that Korean consumers have a deep-rooted distrust of auto repair shops. There is a widespread perception that some unknowledgeable companies “sell parts” by insisting on unconditional replacement of parts or presenting expensive quotes that are difficult to understand, even if you visit them with minor malfunctions. “We are committed to providing the highest level of satisfaction to our customers through transparency, honesty and maintenance, and the role of our employees is paramount to this. Therefore, I strive to create an environment where employees can enjoy their work by providing them with satisfactory welfare benefits and treating them like family with the mindset that they are the owners of the company.” says Lee. He travels more than 10,000 kilometers every month to deliver the highest level of satisfaction to customers across the country to be the best in the field.

김태인 기자 red3955@hanmail.net